PC To TV (VGA to Scart) Signal Converter

Here is the circuit for VGA to scart connection. It is basically a circuit which takes VGA signals and converts it to RGB + composite sync signal which can be fed to TV via SCART connector. VGA card picture components RED, GREEN and BLUE are already at the correct voltage level (0.7Vpp) and has correct impedance (75 ohm) for direct connection to correspondign inputs in the TV. What needs to be done is to combine separate horizonal and vertical sync signal from VGA card to one composite sync signal which is feed to TV video in pin in SCART connector. This sync signal conversion is done by the electronics in the circuit. The circuit has also sends correct level signal to the TV RGB input enabling control pin in the SCART connector (pin 16).

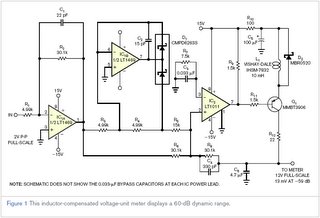

VGA to Scart Schematic (click to view):

How the circuit works

This circuit is designed for converting normal VGA signals standard RGB signals and composite sync signal. The circuit is quite simple, because RGB signal ouput from VGA card is already standard 0.7Vpp to 75 ohm load. RGB+composite video format is the signal format needed by the TV input. Besides that format conversion special drivers is needed to set the VGA card to suitable refresh rate for normal TV.

For sync signals there is a circuit which combines horizonal and vertical sync signals to from composite sync singals. The circuit is simply based on one TTL chip with four XOR ports, two resistors and two capacitors. TTL chip was logical choise because VGA sync signals are TTL level signals.

The sync signal combiner has a system to adjust to different sync polarities so that it always makes correct composite sync signals. VGA card uses different sync signal polarities to tell the monitor which resolution is used. This circuit adjusts to sync signal polarity changes in less than 200 milliseconds, which is faster than setting time of a normal VGA monitor in the display mode change.

The circuit needs well regulates +5V (+/-5%) power supply and takes about 120 mA current.

Circuit PCB Layout:

Building the circuits

VGA to TV converter is quite easy to build if you have some experience in building electronic circuits. The electronics of the circuits can be easily built to a small piece of veroboard and no special circuit board is needed. I used this approach in my prototype.

Remember to add powerfeed to the chip U1. It has not been marked to the schematic. U1 has ground at pin 7 and +5V power input at pin 14.

The circuit need well-stabilized power +5V power source (actual voltage can be in 4.75V to 5.25V range). The circuit takes less than 150 mA current, so you don't need a large power supply. If you don't have anythign suitable avalable, you can always use a small general purpose wall transformer and a small +5V voltage regulation circuit. If your computer graphics card is VESA DDC compliant, it might have +5V available at VGA connector pin 9 (the standard have option that VGA card can have +5V at pin 9, but it does not necessarily have to have this). You can test easily if your computer has this +5V output using multimeter.

Final Circuit:

VGA to TV converter component list:

Main circui tU1 74LS86 (74HC86 or 74HCT86 can also be used)

C1 22 microfarads 16V electrolytic capacitor

C2 use 47 uF 16V electrolytic for more reliable operation (22 uF listed schematic can cause problems in some cases)

R1,R2 2.2 kohm, 1/4 W

R3,R4,R5 2.2 kohm, 1/4 W

R6,R7,R9 47 ohm, 1/2 W

R8 120 ohm, 1/2 W

T1,T2 BC547B (2N2222 should also work but note the different pinout)

P1 15 pin SUB-D connector (DE-15)

Output connector: 21 pin EURO/SCART connector

Wiring: Red, Green, Blue and Composite Sync lines should be wired using 75 ohm coaxial cable for best picture quality, but can be replaced with normal shielded wire.

Power supply components:

7805 regulator chip

100 uF electrolytic 25V

10 uF electrolytic 16V

100 nF polyester or ceramic condensator

Wall adapter which outputs 8-18V DC and 150 mA or more current

Connector for connecting wall adaptor to circuit

Warning and disclaimer

If you try this circuit and those drivers and do something wrong, there is danger that you damage your TV, graphics card and monitor. So think what you do and double check everything. And remember that you try this at your own risk: I am not responsible if something harmful happens. The material in the document have been checked and is beleieved to be correct, but there is always possibility of errors. And remeber that there are some differences in different graphics cards and TVs, so it is possible that the circuit might not work in your system for some reason. The system has been tested succesfully with 6 different graphics card in 5 different computers using 6 different TVs/monitors

Source Tkk.fi